You are here: Home >> Products

- Introduction

-

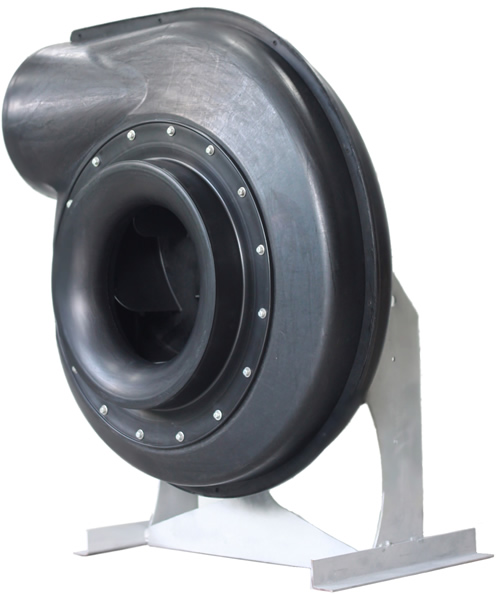

CHEB's high efficiency chemical resistant plastic fan developed to handle heavy corrosive fumes, vapours, contaminated air and aggressive gases. The backward curve impellers' diameters from 315mm to 1250mm dia of thermoplastic such as PP, PE, PVC, PVDF etc. The fan can be blended with composites to overcoming high temperature, flame retardant resistant, ultraviolet or Electrostatic Discharge protection. Tested and rated in accordance with BSI and AMCA standards. Noise accordance to DIN 45635. Balanced in accordance with Grade G2.5 of BS 5625 Part 1 (1979). You may also email us to request for full catalogue and information

- Application

-

• pulp and paper • wastewater-treatment • fertilizer • pharmaceutical • metalplating • laboratory fume hoods • small plating and pickling operations • etching processes • chemical-fume scrubbers • soil remediation

- Operating Range

-

• Maximum CMH: 180,000 • Maximum Static Pressure: 7,000Pa • Maximum Temperature: 80° • Fan Sizes: 315mm to 1250mm - Options

-

• Coat fan base • Flanged outlet • Transition • Belt guard • Motor and drive canopy • Spark resistant construction • Motor and drive mounting • Flanged inlet • powder coated fan base • hot dipped fan base - Feature

-

• High efficiency centrifugal chemical resistant plastic fans designed with backward curved impeller • Smooth PP reduces friction and minimizes solids build-up • Polypropylene composition impervious to extreme outside environments • Performance data is the result of testing in accordance with AMCA standard test codes